How Proper Coding and Marking Help Prevent Product Recalls

- George Bouton

- May 30, 2023

- 4 min read

Proper Identification Enhances Efficiency

In today’s fast-paced, competitive market, businesses face numerous challenges to ensure the safety and reliability of their products. One of the most detrimental setbacks a company can experience is a product recall. Not only do recalls tarnish a brand’s reputation and erode customer trust, but they also lead to significant financial losses and even potential legal liabilities. Fortunately, businesses can take proactive measures to minimize the risk of recalls, and one crucial aspect lies in the realm of proper coding and marking.

Coding and marking may seem like mundane technicalities, but their importance cannot be understated. They serve as the backbone of product identification, traceability, and compliance within supply chains. By implementing robust coding and marking systems, businesses can significantly reduce the likelihood of recalls, thereby safeguarding their reputation and bottom line.

Understanding Product Recalls

A product recall is when a company removes a product from the market due to safety concerns or defects. It is a process designed to protect consumers. Product recalls can take different forms depending on the nature of the issue and the level of risk.

Safety Recall: This type of recall occurs when a product poses a risk to consumer health or safety. It could be due to flaws, defects, or other factors that could result in injury, illness, or even death. Safety recalls are the most serious and urgent recalls.

Quality Recall: A quality recall is when a product's quality falls below acceptable standards. It is worth noting a quality recall may happen, even though it may not pose an immediate safety hazard. This type of recall addresses issues that affect a product's performance, reliability, or durability. Although quality recalls may not directly endanger consumers, they can still result in dissatisfaction, customer complaints, and potential liability for the manufacturer.

Labeling Recall: A labeling recall is necessary when product labels contain incorrect information. This could include false ingredient listings, inadequate warnings, or confusing instructions. Labeling recalls ensure there is no information on packaging that could mislead consumers. Incorrect ingredient lists can also pose risks to individuals with allergies.

Packaging Recall: This recall is for when there are issues with the packaging itself. Packaging recalls are not declared for cosmetic reasons. They are only used when faulty packaging can compromise the safety or quality of the product.

Market Withdrawal: While not a recall, companies will post warnings for products with minor defects. It is worth noting that market withdrawals are voluntary for products that do not pose an immediate safety risk.

The Role of Coding and Marking in Product Identification

Product identification is crucial for ensuring safety. When products are clearly labeled and identified, it becomes easier to recognize potential hazards or risks. Whether it's a warning label about choking hazards on children's toys or an expiration date on food products, proper identification helps consumers make informed choices and avoid using products that could be harmful. Additionally, in the event of a safety concern or product recall, effective product identification enables swift and targeted action to remove or rectify the problem. By prioritizing product identification, companies and regulatory bodies can work together to create a safer environment for consumers and protect them from potential dangers.

Coding and marking technologies are essential tools used to apply identification to products, packaging, and labels. These technologies enable businesses to incorporate crucial details such as batch numbers, expiration dates, barcodes, and product-specific information onto their products. There are various coding and marking methods available, including inkjet printing, laser marking, thermal printing, and labeling systems. Inkjet printing utilizes small nozzles to spray ink onto the surface, while laser marking employs lasers to etch or engrave codes. Thermal printing uses heat to transfer ink onto labels or packaging, and labeling systems apply pre-printed labels onto products. These technologies offer versatility, allowing for precise and consistent marking on a wide range of materials, including plastics, glass, metals, and paper.

Ensuring Product Safety and Compliance

By assigning unique codes or identifiers to each batch or lot of products, companies can effectively track and trace their products throughout the entire supply chain. Coding and marking technologies enable the seamless application of these identifiers on product packaging or labels. This allows for accurate and efficient monitoring of product movement, enabling quick identification and recall of specific batches in case of safety concerns or quality issues.

Regulatory agencies often mandate specific information to be included on product labels or packaging, such as ingredient lists, warning labels, country of origin, expiration dates, and safety symbols. Accurate coding and marking technologies enable companies to consistently and precisely apply this required information, ensuring that products meet the necessary regulatory standards. Compliance with regulatory requirements not only helps protect consumer safety but also builds trust and credibility with authorities and customers.

By incorporating unique identification codes, serial numbers, or authentication features onto products and packaging, businesses can establish a robust system to verify product authenticity. This enables consumers, retailers, and authorities to distinguish genuine products from counterfeit ones. Additionally, advanced coding techniques, such as covert or tamper-evident codes, can provide additional layers of security, making it more difficult for counterfeiters to replicate or alter the coding.

Bespoke Coding Solutions for your Business

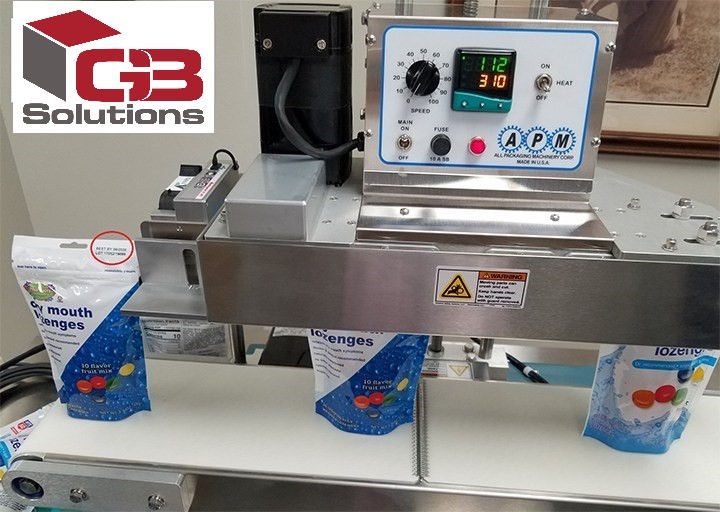

GCB Solutions is one of the few packaging companies able to offer all types of coding technology. Our focus is growing long-term relationships with our clients and doing our best to prevent product recalls through proper use of coding and marking.

Call us at (904) 263-2804 or schedule a free consultation today!

Expunging a record should feel like closing a chapter, but too often it doesn’t erase the past from every database or employer’s screening process. Even after the court clears your record, outdated reports or background check errors can continue to block opportunities you deserve. For a detailed breakdown on how to enforce your rights and ensure your expunged record actually opens doors, check out https://consumerattorneys.com/article/got-your-record-expunged-but-are-still-being-denied-employment. Taking action with the right legal guidance can turn those dead ends into a clear path forward.

The potential impact of a Product recall on a business can be immense, making this specialized insurance absolutely vital.